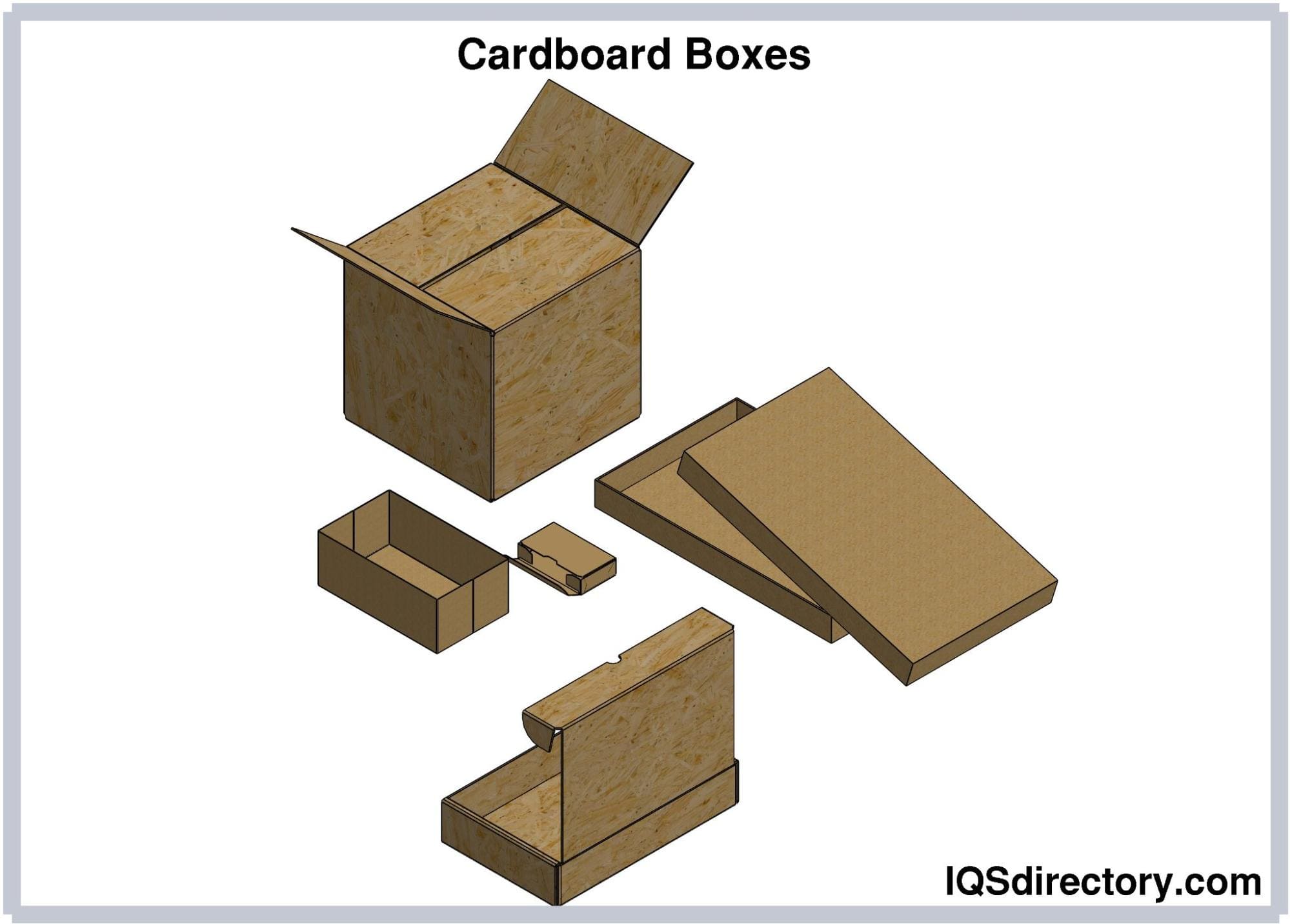

Chipboard boxes are inexpensive, environmentally friendly, and a popular packaging option for consumer goods. Chipboard is made from pieces of recycled paper, wood pulp, sawdust, or chips that have been compressed by using heat and pressure and bonded by an adhesive material or resin. You often see chipboard or paperboard in brown or white, but most companies add colors or logos so they can be sold in stores. Read More…

At Deluxe Packaging, our goal is to always create a cost-effective solution for you and to service you better than anyone else. We offer a full array of high quality corrugated boxes in a variety of shapes, sizes, materials, and features. Deluxe Packaging has a proven track record in custom packaging design and timely delivery.

At Nelson Container Corporation, we pride ourselves on being a leading provider of innovative packaging solutions. Our core focus revolves around the creation of high-quality corrugated boxes designed to meet the diverse needs of our clients. We understand that packaging is more than just a container; it is a critical aspect of product protection, brand representation, and logistical efficiency.

At Imperial Paper Company, we specialize in crafting top-quality corrugated boxes that cater to diverse packaging needs across various industries. Our team of experts designs these boxes to ensure maximum protection for your products during transit, storage, or display.

At Volk Packaging Corporation, we are passionate about delivering high-quality corrugated boxes and innovative packaging solutions to our valued customers. With decades of experience in the industry, we have established ourselves as a leading provider of customized packaging products and services. Our primary focus is on manufacturing corrugated boxes that meet the diverse packaging needs of...

Corrugated boxes are the industry standard! All cartons are constructed from strong 200#/32ect, kraft corrugated (unless otherwise noted). Order in bundle or bale quantities. 100`s of sizes to choose from! All boxes ship and store flat to save space. Corrugated boxes are all 100% recyclable. Protect your large shipments with cargo containers! Makes a great master pack for smaller boxes. Protect...

At Associated Bag, we have built a reputation among many industries by providing a broad range of high-quality corrugated boxes and exceptional customer service. Our 6-month quote guarantee is unequalled in our industry, giving our customers the flexibility to order whenever the time is best for them.Our line of boxes include corrugated shipping boxes, insulated boxes, and more. Contact...

More Chipboard Box Manufacturers

Chipboard boxes are used in a wide variety of industries. For shipping, they are usually coated in a waterproof finish to protect the product from outdoor elements and uses a thinner chipboard layer for protection, while thicker boards form the outer box component. They are also used in the food processing, consumer product, and tool industries. Most chipboard boxes are custom made to hold specific products found on shelves in retail stores. You can find these are made of a single sheet with flaps for closing, or they can come in two pieces, one of which is a lid.

Raw materials such as used paper shreds, sawdust, and woodchips are used in the fabrication process while making chipboard boxes. These products are put through a chipper to become fine granules and then are dried until there is no longer moisture left in the wood product. Adhesives are added for the pressing process and exposed to high temperatures until the desired thickness is achieved. The bond between the materials is created by the adhesive elements melting. After the cooling process, several treatments are conducted before the chipboard can be formed into a box shape. Sanding and coating with a waterproof finish is often added depending on the application. The large sheets are then cut down into different sizes. Chipboard used as packaging for retail products require lamination of a decorative layer of brightly colored paper material. After they have been shipped, the chipboard material is folded and assembled into a box form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

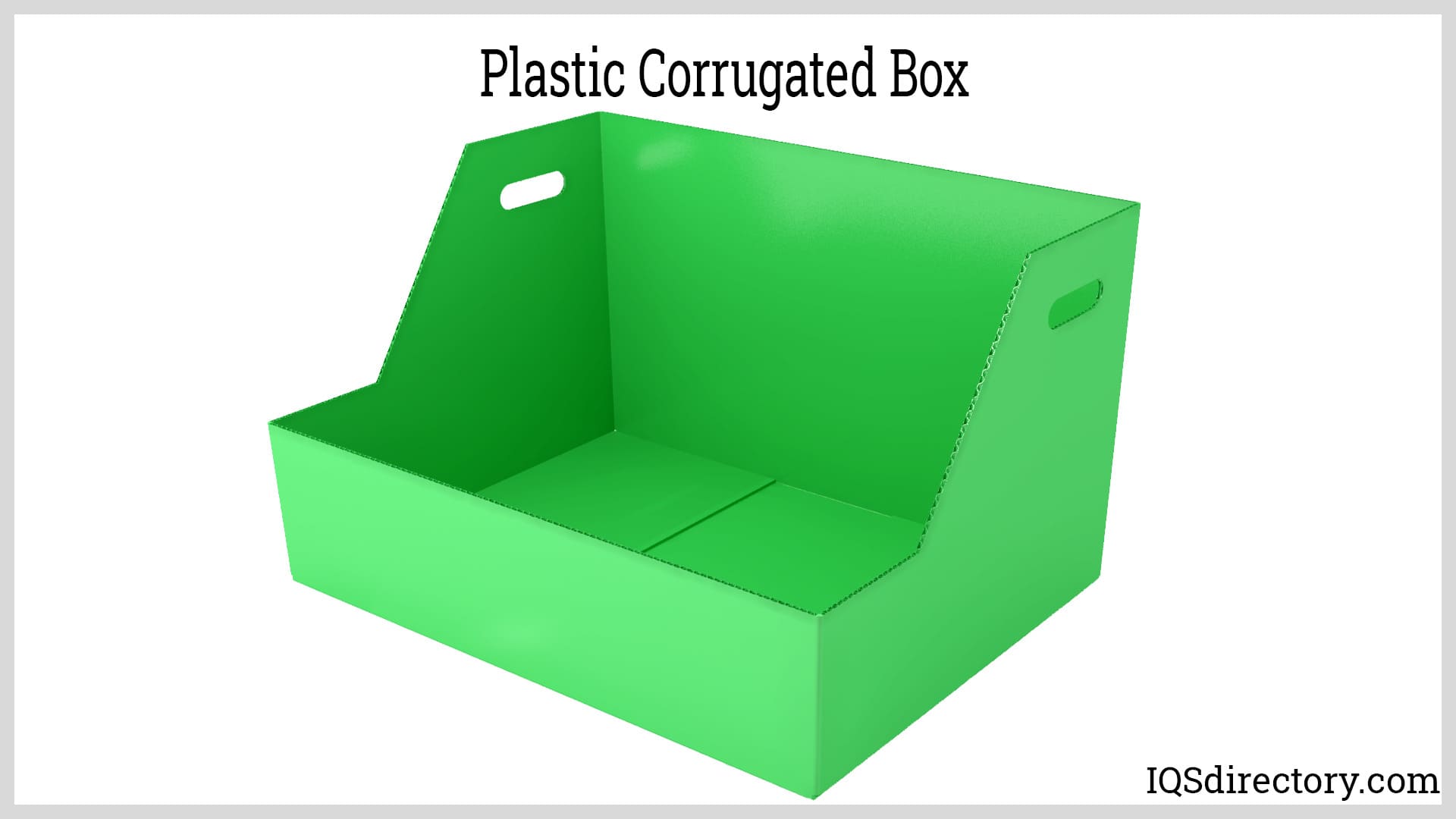

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services