Corrugated plastic boxes are often used when cardboard boxes are unable to be implemented due to storage that cannot be met by cardboard containers. Heavy objects, some food and medical products are some examples of items that are in need of a durable box such as plastic. Recycling bins are often exposed to spilled liquids and sticky substances and can be cleaned unlike bins made of cardboard-which would degrade or deteriorate after the exposure of cleaning supplies. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Corrugated Plastic Box Manufacturers

Plastic is preferred when exposure to liquids, impact, or heavy materials is likely. These are often used in waste management, food transportation, medical packaging, and many more industries. Choosing a paper or plastic container should be based on the purpose and demands of your application.

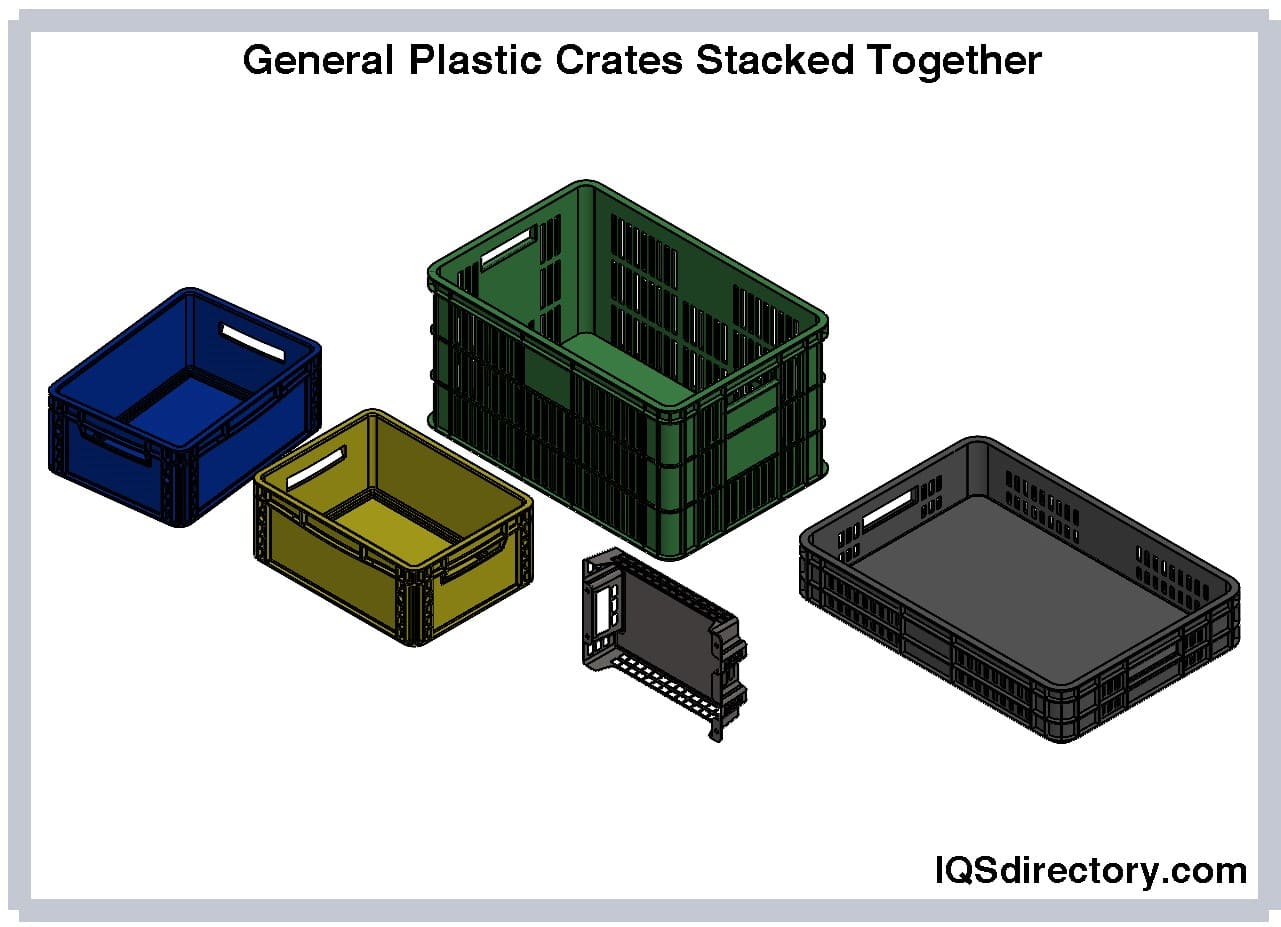

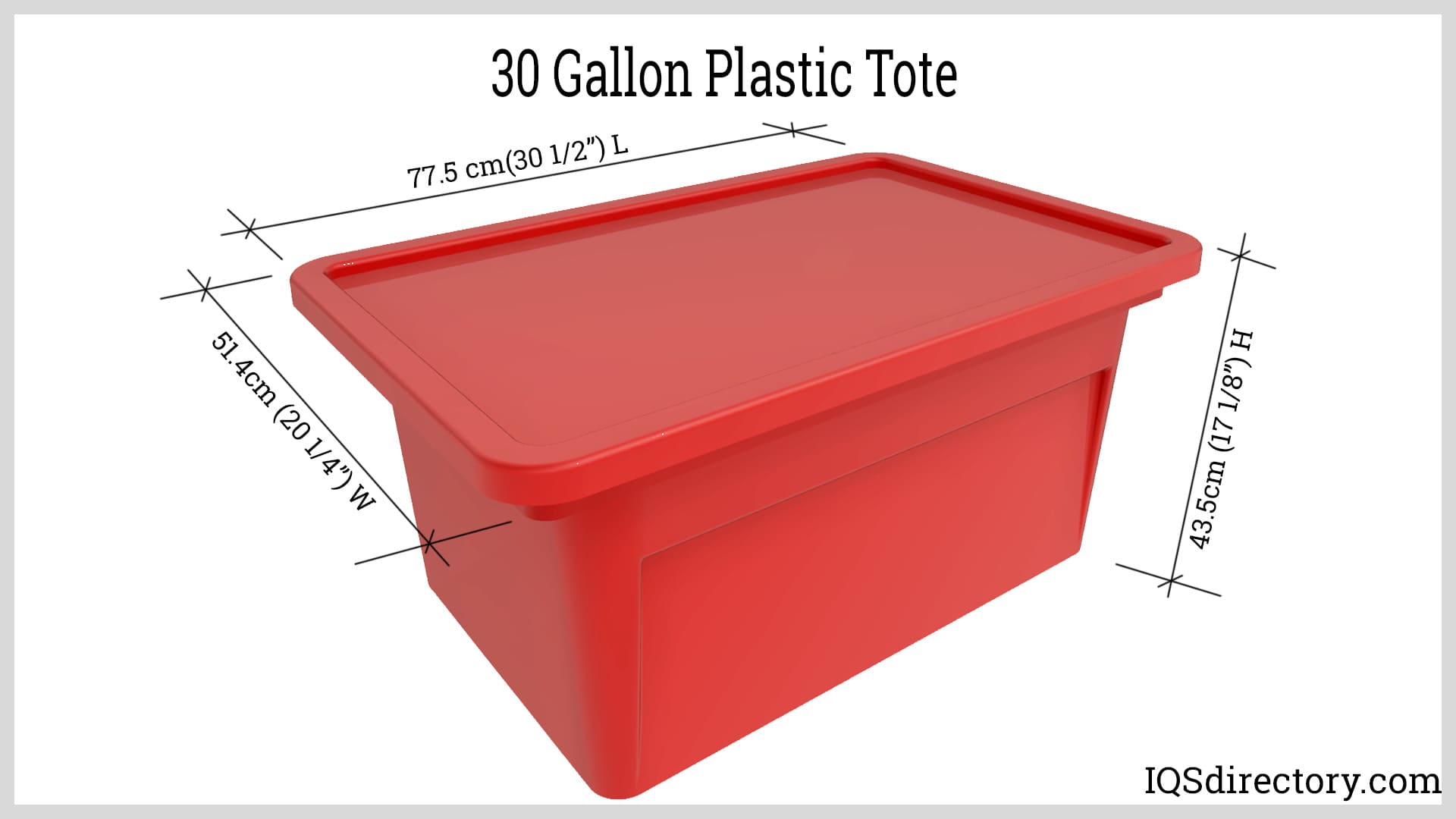

Corrugated plastic boxes are made from a wide range of extruded, twin wall plastic sheet products. The plastics that are normally used include high-impact polypropylene resin, polyethylene, vinyl and many other plastic varieties. Similar to corrugated paperboard, they are made with two sheets of plastic surrounding an inner fluted sheet. This fluted process creates air pillows to provide durability and impact-resistance. Corrugated boxes are often made in many sizes and shapes, and offer countless advantages over the basic cardboard box. Since plastic is moisture and mold resistant, it is stronger and more useful to resist some chemicals used in different industries. More benefits of plastic boxes include the ability to be stacked, locked, and folded flat for storage purposes. Although they are not as easily recycled compared to cardboard or paper, they are still capable of being recycled.

The disadvantages of plastic boxes include pricing and bulk. The up-front cost and replacement costs for plastic boxes is much higher than cardboard or paperboard boxes, which is why it is important to determine the application before purchase. They are also much heavier than cardboard containers of similar sizes.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services